Services

CNC turning

On CNC turning lathes from a recognized Japanese producer MAZAK, we carry out turning of workpieces from the smallest diameter Ø 10 mm to Ø 450 mm and with max. turning length L=1500 mm.

Our machine park includes 8 CNC turning lathes with different characteristics:

- turning lathes with driven tools (e.g. with capacity of thread cutting up to M16 mm),

- double-spindle turning lathes which allow turning of workpieces on both sides – in one clamping, providing very accurate machining on one side in regard to the other side of workpiece;

- turning lathes with a feeding device; these are meant for the manufacture of pieces out of bars, etc.

These machines guarantee the highest accuracy of machining till 0.01 mm!

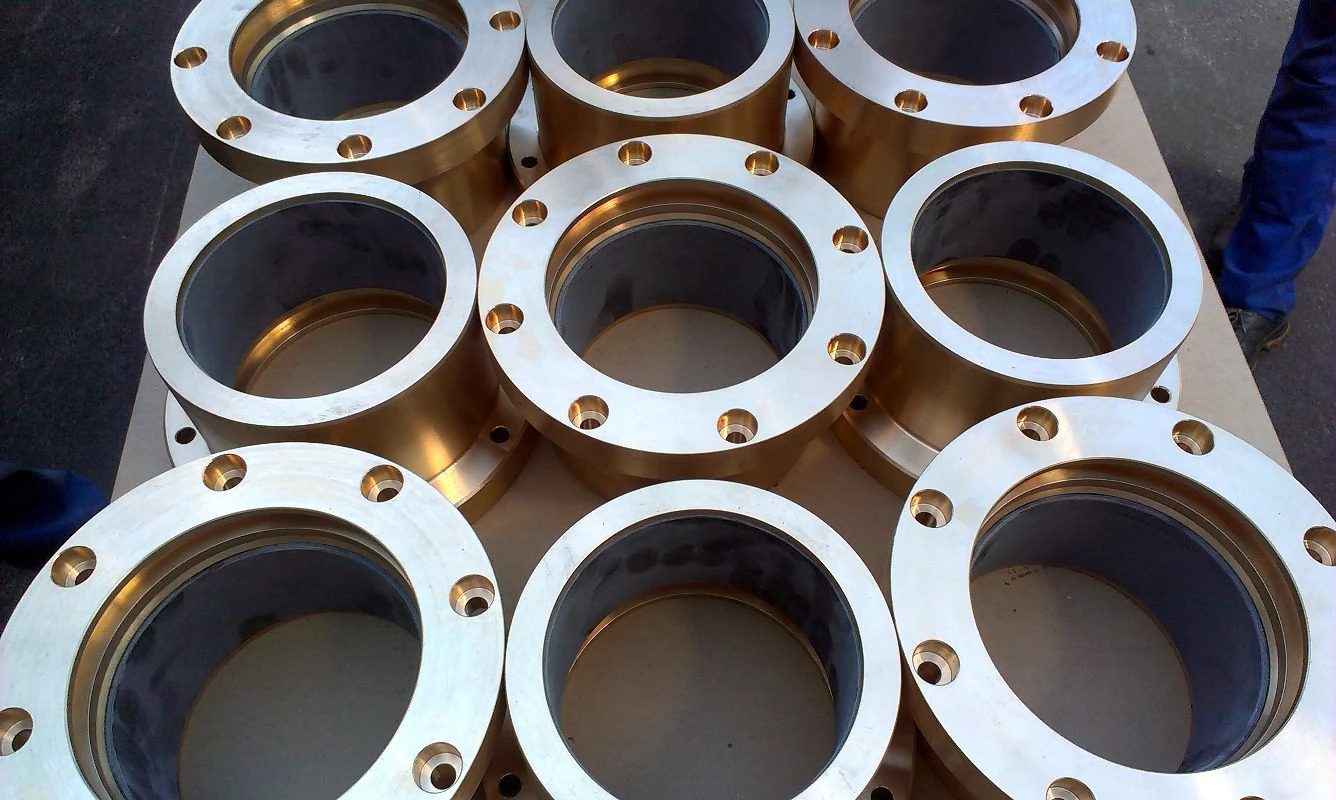

Machining is made on various pieces; from the most simple bolts, bushes, nuts, screws …. to highly demanding axles, shafts with nuts and special thread pitches …

Workpieces are made from different materials like steel, INOX, ALU-plastics, bronze, castings and also hardened materials with hardness up to approx. 60 HRC.

Our products are meant in particular for different hydraulic components, hoisting devices, cranes, lifting platforms, transport devices, hydroelectric power plants, etc.

CNC milling

We offer a wide spectrum of milling services on our CNC vertical and horizontal milling machines from a recognized Japanese producer of machines, MAZAK.

1. Vertical milling machines

- Our largest machine has a worktable of 750×1750 mm and a manifold (stepless adjustable program – 4th axle) which among others allows machining of workpieces under different angles, spiral milling, etc.

- We have machines with changing tables which allow the highest intensity of machining (no dead time for workpiece clamping).

- Our larger, stable vertical machines are provided with ISO 50 clamping which ensures a more stable machining process. In addition, we have a machine with up to 25.000 min-1 revolutions which is ideal for machining of workpieces from ALU and similar materials demanding higher revolutions.

2. Horizontal milling machines

- Both machines have changing tables of 680×680 mm which increase machining intensity, with no dead times necessary for workpiece clamping.

- One machine has a steplessly adjusted revolving table (4th axle) which allows the manufacture of worms, spirals, etc.

- Today, we are planning to buy a new, larger horizontal milling machine MAZAK HCN 8800 which will make it possible for us to clamp even larger workpieces (max. Ø1450mmx1450mm) in addition to highly efficient machining ensured by a spindle with 10,000 min-1 and 37 KW power. It will in addition to a continuous 4th axle (revolving table) provide for external and internal turning or shaping of workpieces.

These machines are distinguished for extreme accuracy of machining up to 0.01 mm!

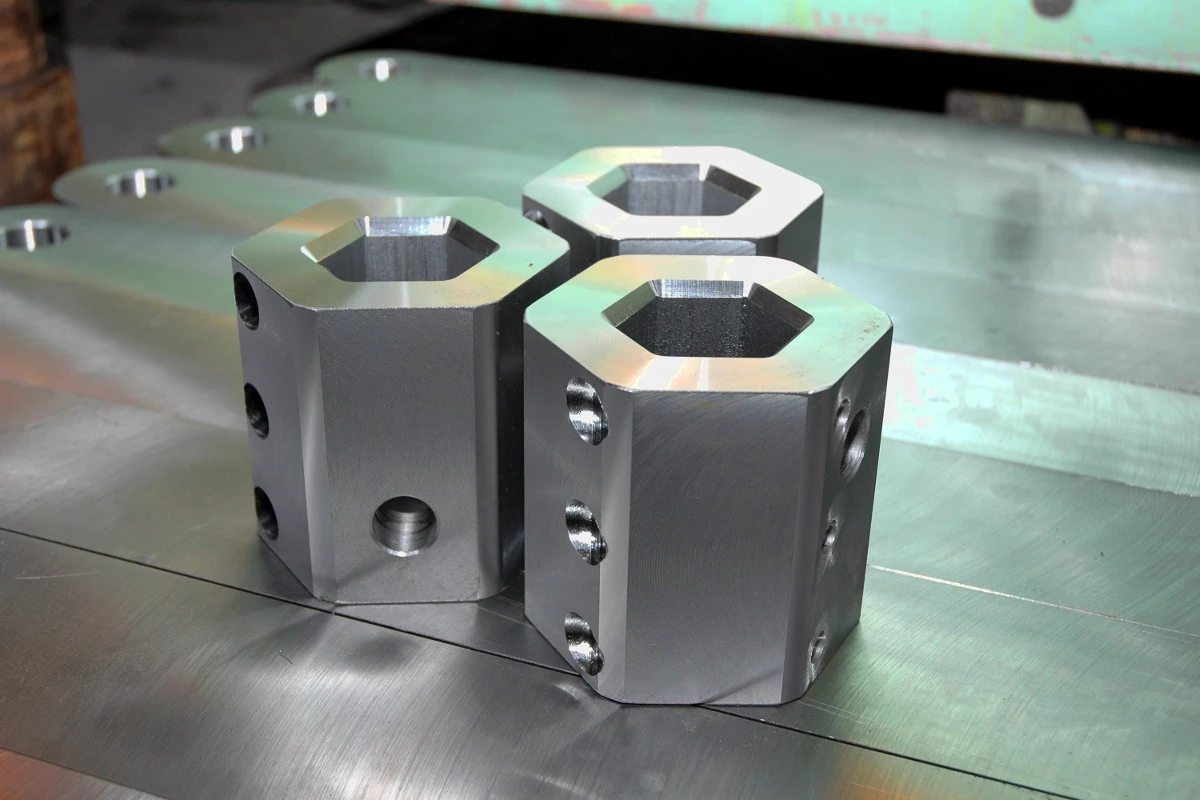

Workpieces from various materials can be machined, e.g. all sorts of steel, INOX, ALU, plastics, bronze, various castings, forgings and hardened materials up to 60 HRC hardness.

Our products are meant in particular for hydraulic motors, hoisting equipment, cranes, mechanical engineering, transport devices, turbines, etc.

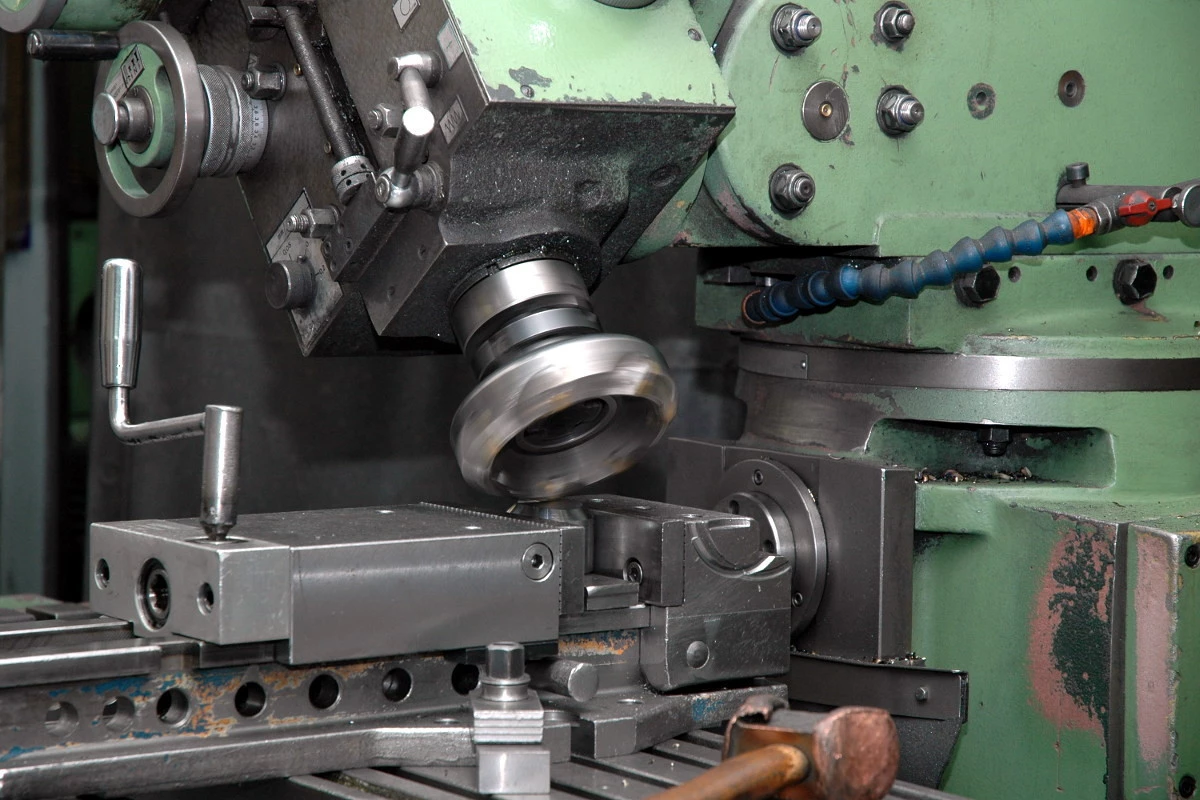

Conventional machining

In addition to modern CNC machines, we also have machines for conventional machining which are indispensable for our production. They are used for the production of spare parts and smaller series of products (even just 1 piece) which are just as necessary in different productions.

Although some series are small, they demand many very different machining processes and accuracy which we can guarantee with the following machines: turning, milling, drilling, slotting, gearing.

Products made on these machines are used mostly as spare parts for machines and devices, but also for the first incorporation into machines for a special purpose in various industrial branches, e.g. medicine, industry, agriculture, construction, …

Metal working and machine engineering

Ever since our company was established far back in 1972 (already at the old location), mechanical engineering and general metal working have been an integral part of our machining offer.

Alone or together with a project design company located in our vicinity, we produce many different machines and devices which are used in industry (woodworking, metal, rubber industries).Many machines and plants have been produced in that time, starting from the first idea to an end product, which successfuly operate today in Slovenia as well as in a broader Europe. This is also confirmed by our satisfied customers who come back to us again and again when they have a requirement.

Recently, the need for the production of a large variety of welded pieces has been continuously growing. Workpieces are first welded and then completely machined. This is very interesting for end customers and reasonable from the aspect of pricing since complete service is carried out on one place.

Our fitters – welders have adequate A-Certificates for welding which are continuously renewed.

Our highly skilled workers work on the following machines:

- different welding devices,

- hand plasma,

- sheet metal bending machine,

- hydraulic shear for sheet metal,

- etc.

We guarantee competitive delivery of laser-cut pieces, if necessary also bent, welded or machined.

Stainless steel program

Our company has a completely separate hall where various equipment from INOX has been produced since the very beginning of our company. First, we started with the production of vinicultural and cellar equipment for end customers in Germany. These were machines like:

- bottle washing machines,

- wine pumps,

- wine filters,

- bottling equipment for various beverages,

- bottle tops,

- labeling machines,

- etc.

Recently, INOX (stainless material) has become easier accessible to end customers and more popular, and today we also produce various outfits for houses, offices and business premises, like:

- railings and fences in different combinations (glass, stone, wood, …),

- staircase,

- terrace and car roofing,

- advertising panels, separating walls,

- exhaust hoods,

- water fountains,

- special kitchen sinks,

- decorative elements for bathrooms,

- etc.

We produce silos and funnels for food industry, equipment for restaurants, pubs and banks. Our products are present in pharmaceutical and production industries working with acid. Therefore complete equipment has to be made from acid-resistant material where our company is also very successful.

In view of our long tradition in machining stainless materials, our products are incorporated in prestigious ships, hotels, kitchens, restaurants and pubs, baker’s shops, banks, pharmaceutical companies, hospitals, health centers, offices, production halls, family houses, …

Assembly

As one of further steps aimed at cost minimization for certain products, we also offer various forms of hired work and assembly of already made components to an end product. We will provide for different assembly materials (e.g. fastening material, seals, bearings, grease, …) as necessary, of the same can be delivered by the customer himself.

We organize

Heat treatment, surface treatment, laser cutting.