Supported by a modern machine park located in our production facility, we are able to deliver flawless products to our customers.

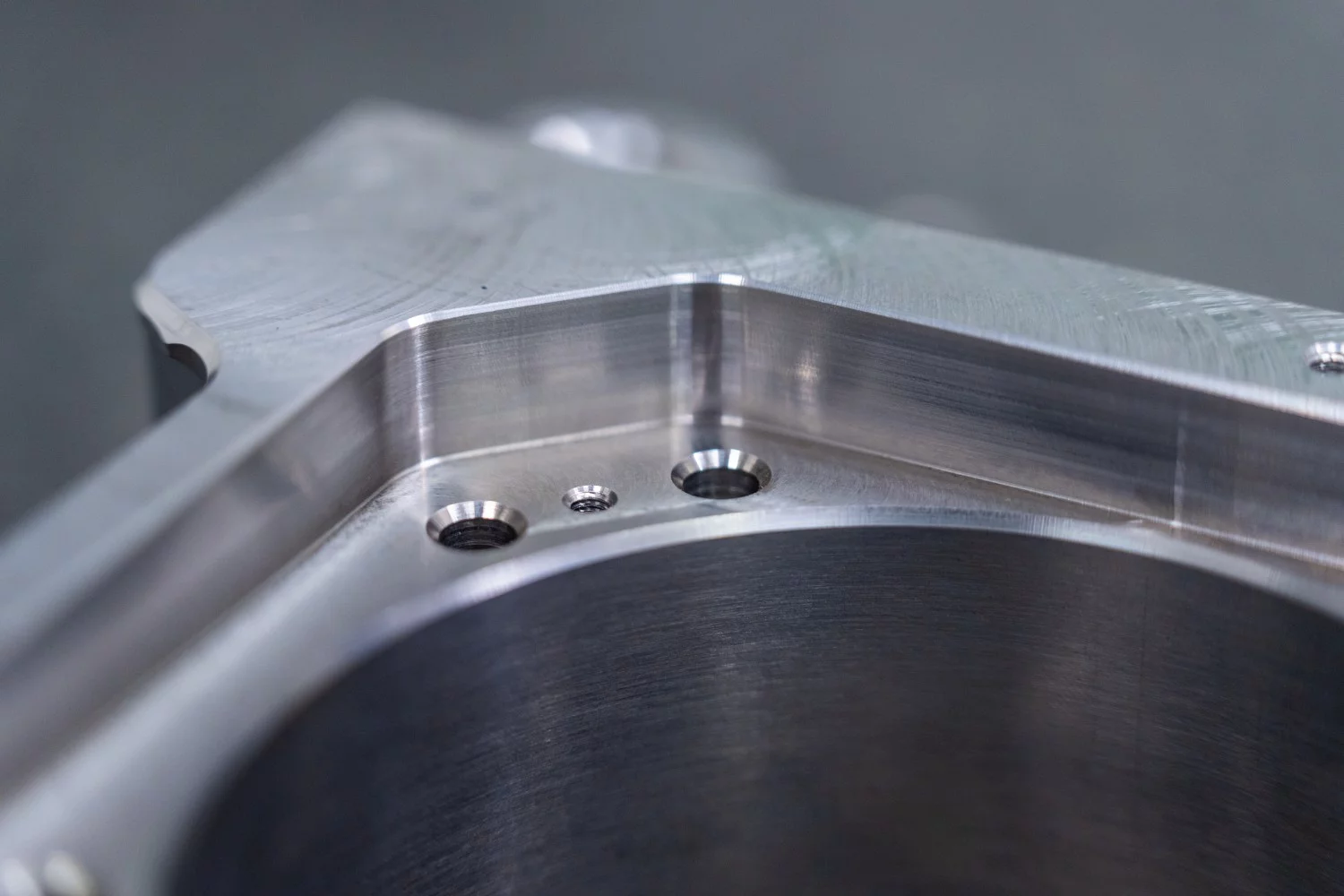

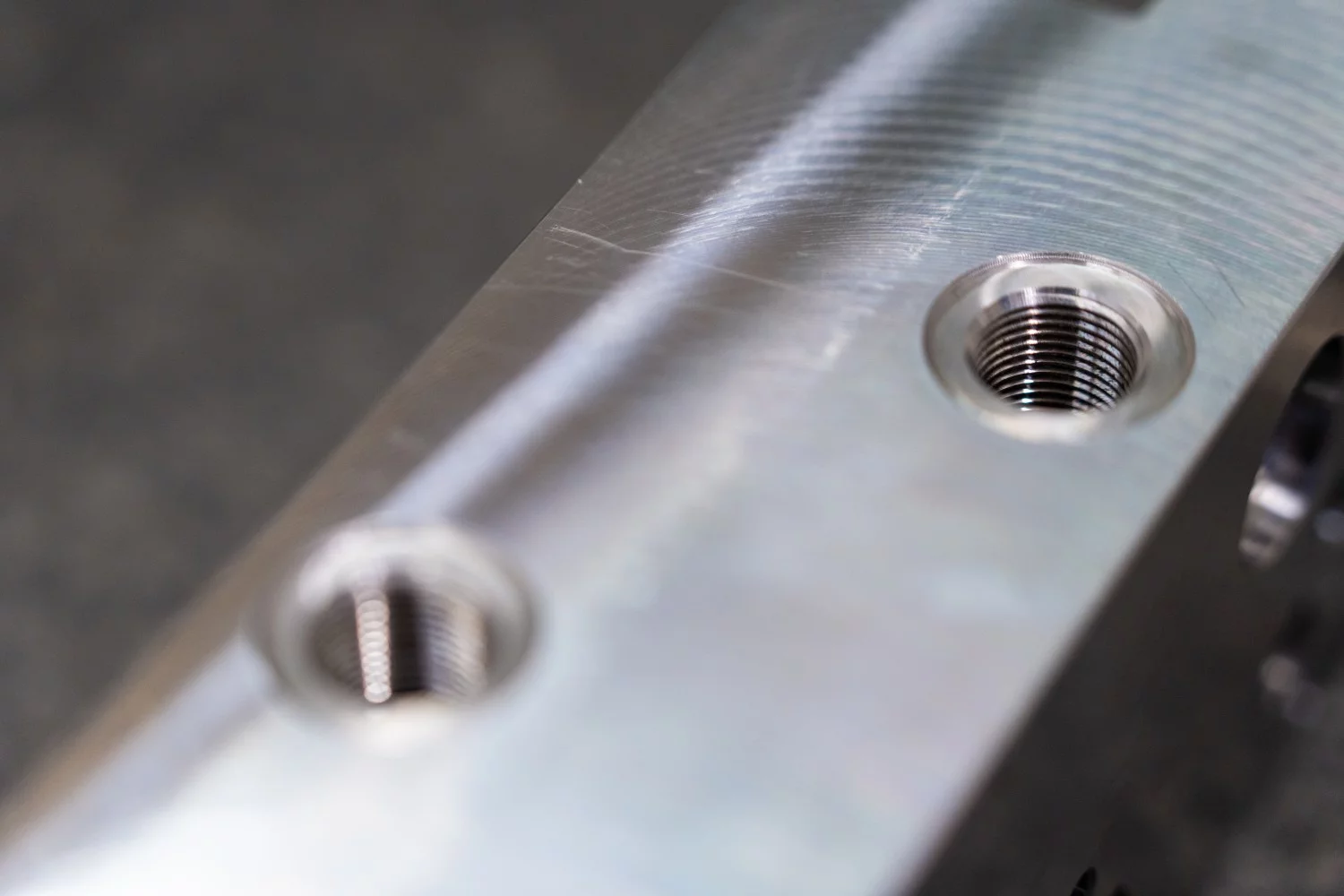

CNC machining is carried out on high-performance MAZAK machines, ensuring exceptional precision and repeatability even for demanding components.

An optimized machining process guarantees fast execution, excellent surface quality, and minimal disruption to your production process.

Contact us